Clothing in Anieth and Ancient Times

Fabrics

Ancient peoples have been wearing clothing for several millennia. People wore furs, and the first clothes were of tanned leather, felted fur, hair and seed fluff, batted and matted plant fibers, and finally about ten thousand years ago, woven fabrics. A woven fabric was made of thread, spun from the hair of animals (wool) or from the fibers of a plant stem (linen) or from the fluffy seed head (cotton.) Silk is spun from the boiled cocoons of the silk moth. In Europe, during the Bronze Age, the making of cloth from flax, hemp and nettles was in full swing.

Hemp and flax are still used today to make cloth. They are both cultivated. Hemp is a stronger fiber from a much taller plant, but, like nettles, must have the outer layer of the stem removed by hand. They are grown in fields, cut down or pulled up after the seed heads mature and the plant is at its tallest. This is usually when the weather is dry. Nettles were once very popular and make a very fine thread, but are not longer grown because harvest of the stinging plant is difficult.

The plants must have the seed heads removed. Using a comb, the flax bundles are pulled through a rippling comb. This also removes any leaves left on the plants. Flax can then be soaked on shallow ponds to "ret" (which smells awful!) to remove the outer layer of the stem. Hemp and nettle stems have to be treated by hand or run through a stripper. (See basketry.) The fibers now have to be beaten to soften them and free the hairs. This process is known as "scutching" and is down with a scutching sword or in a press.

Above, you see these women hacking the flax and heckling it with a long comb. The same must be done with all three fabrics, or any long fibers that you intend to twist into thread.

The material must be dressed on a distaff. This means different things for different fibers. Long plant fibers are bound in carded bundles on a three prong distaff or a distaff with an end like a basket. Wool can be bound to a single distaff. The thread is started by hand and knotted to a spindle.

For centuries before the spinning wheel, people used a drop spindle. It was easy to use, could be used standing, walking, or sitting, inside and out. Different kinds of spindles became the trademark of different cultures, but the process was the same, whereby the spindle was tossed and the thread guided with the fingers to whorl about the shaft. The weight of the spindle pulled the thread down into a nice even yarn. It took so long for a person to weave enough thread to make a piece of fabric that women often were always spinning. The phrase "spinning yarns" means to tell stories, which became one of their chief occupations while their hands were busy. The long threads spun off the fibers had to be doubled and twisted the other way to keep the treads from unraveling.

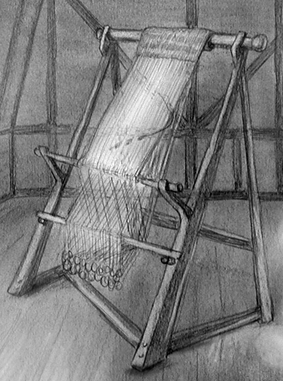

There were many popular looms used in Anieth and in the Bronze Age, most of them upright. The basic loom was one fixed frame that held the warp threads and a sword or horizontal piece that would be woven through the warp threads and opened to create a shed through which the shuttle holding the horizontal threads was passed. In the early days, to keep the fabric taut, the warp threads were weighted with stones.

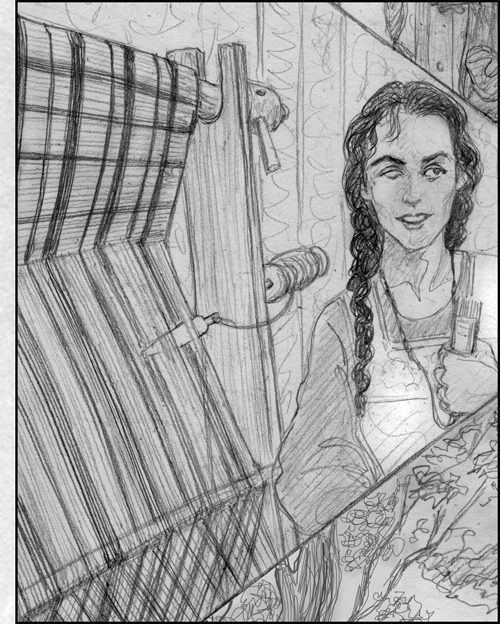

Here, a woman uses a card loom to weave straps. This design was also tied to the worker on a belt and used as a horizontal loom. The cards had complex designs through which the warp threads were strung. This was the first computer and the model for Babbage when he designed his cards for mechanical computers for large industrial looms.

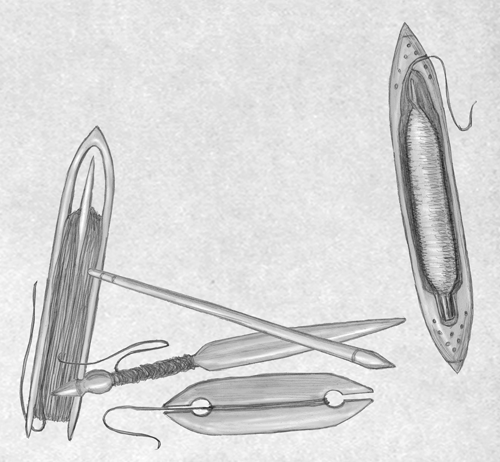

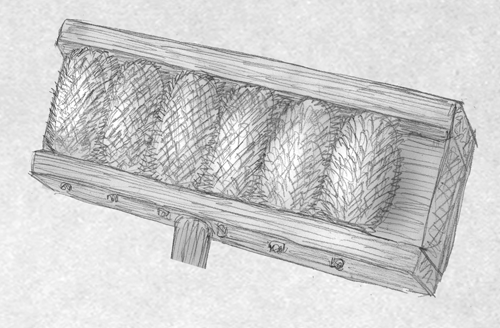

All around the world people still use hand looms to make rugs, straps, and rough fabric. The favored western loom is now a large horizontal loom. Here is a picture of three different shuttles, wound with woof (horizontal) threads, a sword and a prick.

Beater combs were also used to push down the fabric and make it even and tight. Often, they were made of hardwood, bone or ivory. most needles were made of ivory and were very precious.

In Anieth, the Ash and the Holly were known for their beautiful nettle linens. Among the Horse People, woolens were favored. Here is a complex upright loom that locks the warp in place and has shuttles that also can be hung on the loom when not in use. The thread is pulled off the spindle and slid across when the warp shed is changed.

Here is a plaid on the same loom. The fabrics were still made by hand, and this was a full-time production, involving both women and men. One of the radical things done by Ghandi when he fought for Indian independence was to start spinning for Indian cloth making. They were shipping cotton to Britain where it was made by machine and buying it back! He broke the British economic hold on India and broke the myth that men could not do women's work at the same time!

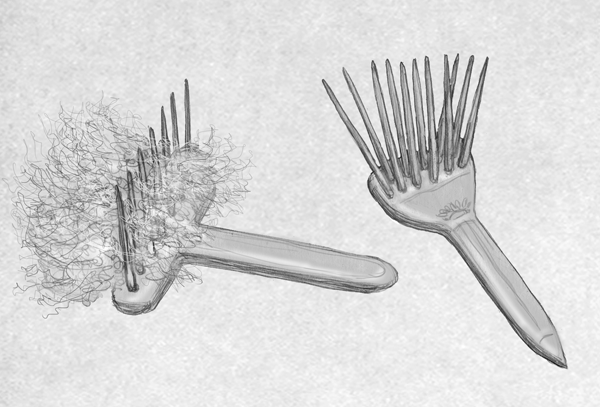

Wool usually came from the fleece of a sheep, looking rather like this Soay. It had to be sheared off the sheep in June, washed, and carded with combs like these until it the hair lined up in long batt. It is pulled off the batt, spun into a worsted thread which is then woven. Again it is double spun to protect from unraveling and then woven, knitted, or crocheted.

For a finer wool, the hairs were teased, with a teasel plant. The seed heads were set into a fram and the wool rolled over them to further untangle it for a finer thread.

Felting

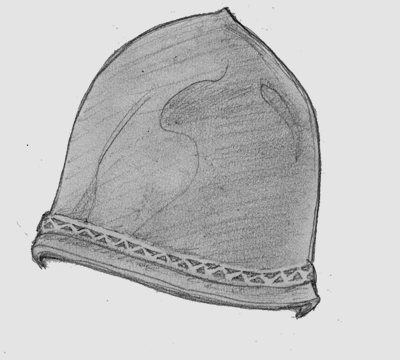

Most weaving is a task for settled peoples. Nomads favored felting, which was the first way to make fabric. It is still used around the world to mash fibers together. Felting worked extremely well for animal furs that could be agitated and compressed so that the hairs stuck together by the tiny scales on the shaft. The best felts are made from alpaca, sheep, mohair goats, rabbits, beavers and muskrats. Beaver hats were made of beaver fur that was felted and were waterproof. The process is easy. The fur is cleaned and gathered into a large mat which is sometimes wetted, but then mashed and rolled and mashed again until it flattens out into a felt. It is often finished by fulling. Wool cloth is also finished by fulling, which is beating the cloth, often using some kind of acid bath like urine to clean it.

After the fabric was made, cut off the warp and hemmed, it was usually washed and dyed. There is a whole science of dyeing, as people discovered which plants would turn which color in the dye bath. Sometimes other minerals and salts were used to turn the fabric a different color using the same plants. Iron would darken colors, alum and copper would brighten them. Urine was again used as a bleach. Even before the fabrics were cut and sewn, there was a very long process from the living plant or animal to a piece of cloth!